Process Quality Control (PQC)

Moulded Components

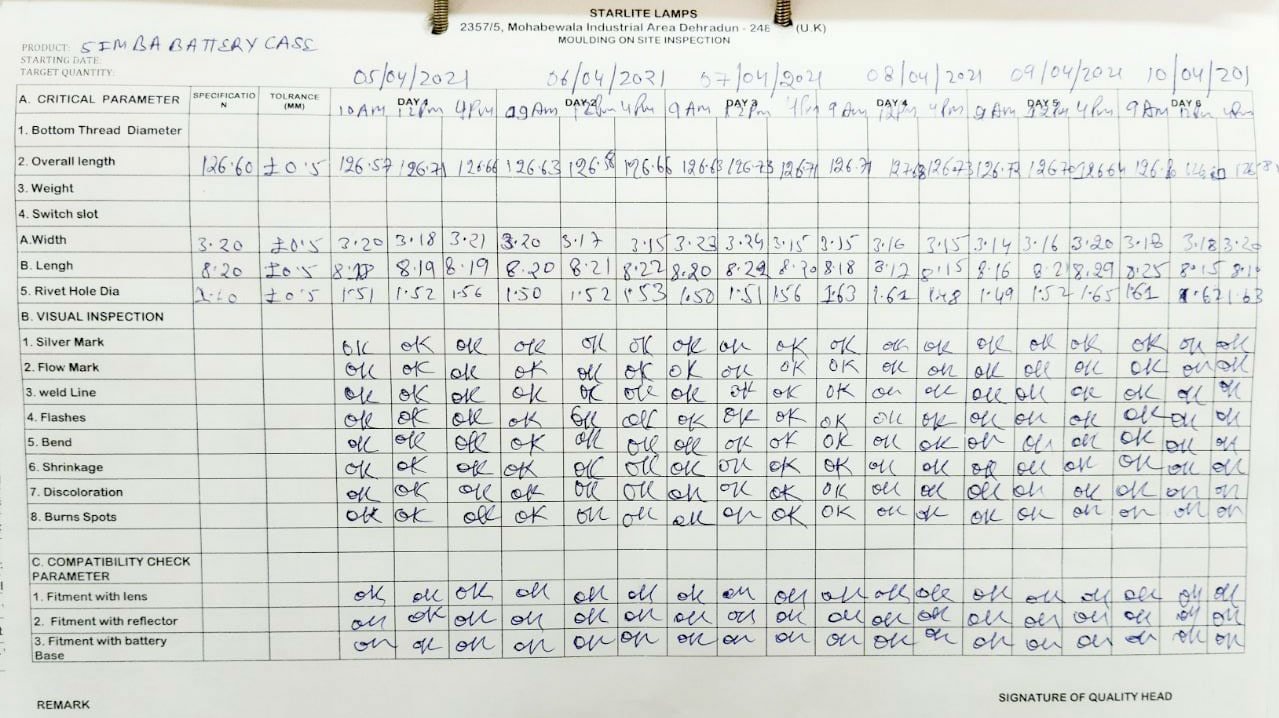

Moulded components are subjected to physical inspection once every 8 hrs. They are checked for all critical parameters. In case any lot is not found suitable for use, the entire lot produced during that shift is put aside and subjected to physical checking piece by piece. Besides these tests the machine operators are given simple jigs or fitment parts so that they can continuously check simple parameters like thread fitting or battery movement. Job cards and Process check sheets are maintained, sample of which is displayed below:

Riveted Components

Fitting of metal components on the plastic moulded body is called riveting, this is a manual process and our QC staff check the quality of riveting and fitment of the meal components every 2 hours to ensure perfect compatibility and durable punching.

Assembly Line Inspection

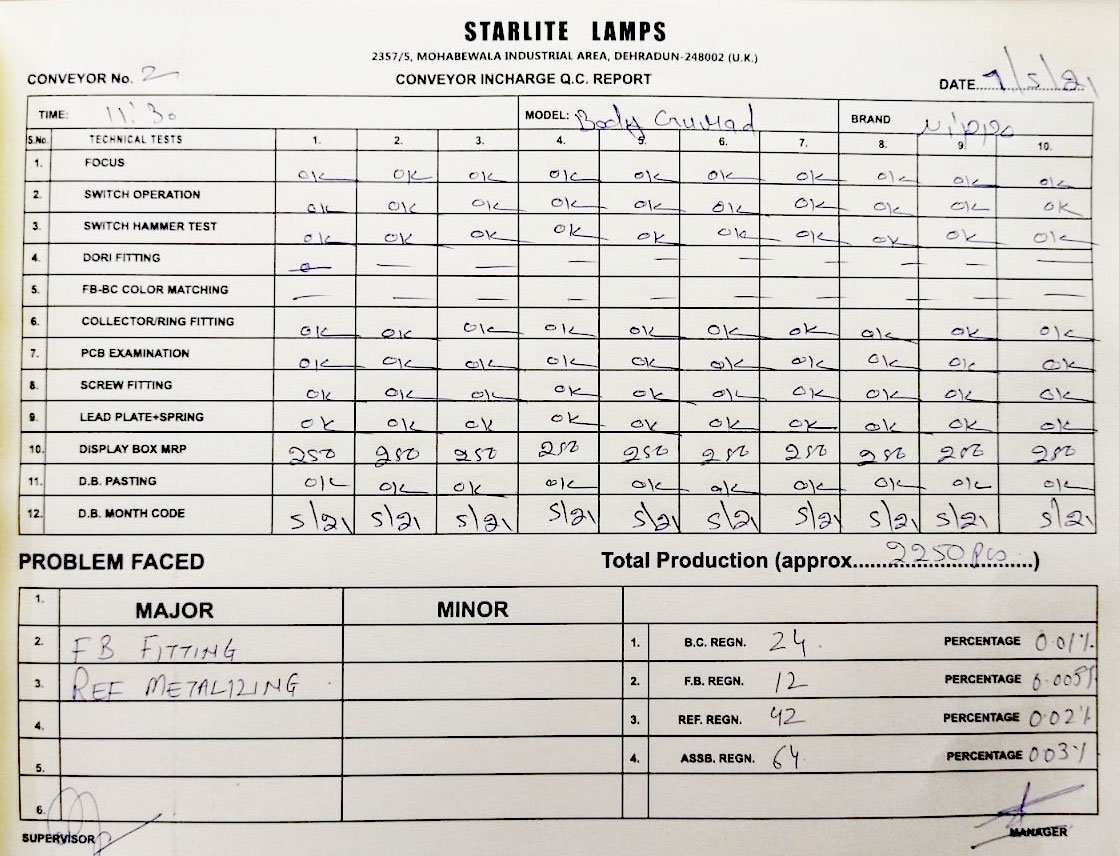

Both our conveyors have individual supervisors who are responsible for ensuring proper quality of the product continuously while the torches are being produced. Continuous checks like drop test, hammer switch test, focus shape etc. are done. A report for the torches being assembled is generated every 4 hours a sample of which is displayed below:

Be Our Business Partner

Our vision is to get the most advanced technology and performance into the hands of everyone across the world while maintaining a simplified and streamlined user experience. We would like you to join us in that Journey.

Become A Partner